When two surfaces come into contact, a phenomenon occurs that is integral to both our understanding of physics and our everyday experiences. This interaction, often described in terms of forces, brings forth a formidable counteraction to motion known as friction. Understanding this force is essential for a comprehensive grasp of dynamics, engineering, and mechanical systems. In this article, we shall delve into the multifaceted nature of friction, its types, characteristics, and its critical role in various applications.

Defining Friction

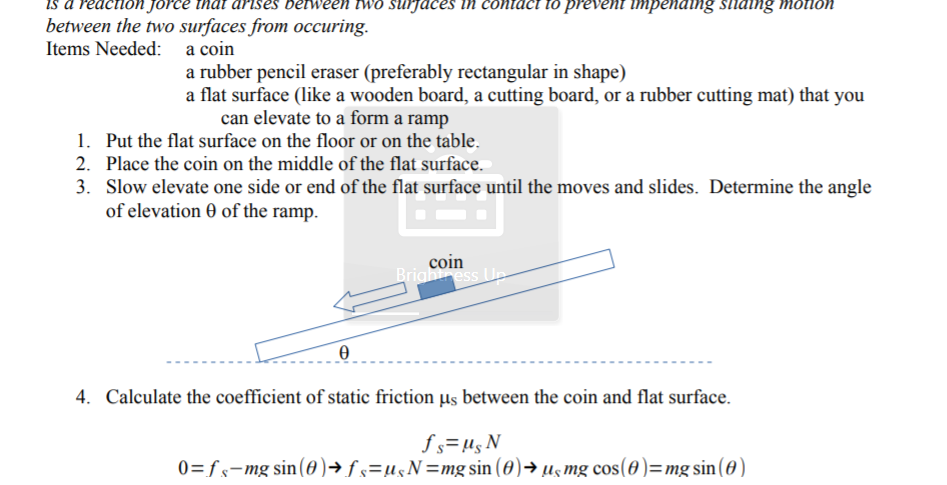

Friction can be defined as the resistive force that opposes the relative motion or attempts of such motion of two surfaces in contact. This resistance arises due to the microscopic roughness of the surfaces involved, which creates interlocking features, as well as the molecular adhesion that occurs at their interface. Depending on the circumstances, friction can either facilitate movement or thwart it entirely.

The Types of Friction

To comprehend friction’s role in counteracting motion, it is necessary to explore its distinct types. Primarily, friction is categorized into two leading forms: static and kinetic.

1. Static Friction

Static friction is the force that keeps an object at rest when it is subjected to external forces. This type of friction acts on an object that is not moving. The static friction force increases up to a certain maximum point, known as the static friction limit, before movement occurs. The coefficient of static friction varies for different materials, indicating that certain surface pairings allow for greater or lesser resistance to initial movement. For example, rubber on concrete may exhibit a much higher coefficient than ice on metal, illustrating how diverse these interactions can be based on surface properties.

2. Kinetic Friction

Kinetic friction, on the other hand, acts on an object that is in motion. Once the force of static friction is overcome, kinetic friction takes over and generally possesses a lower coefficient than static friction. This characteristic is crucial in applications ranging from sliding objects to the functioning of machines. The predictability of kinetic friction allows for better design and control in numerous practical scenarios.

The Characteristics of Friction

Beyond its classification, friction possesses several key characteristics that dictate its behavior. It is important to note that friction is not solely dependent on the nature of the surfaces in contact but also on the magnitude of the forces acting on them. Other factors impacting friction include:

- Surface Roughness: Rougher surfaces typically generate greater friction due to increased interlocking and surface area contact.

- Normal Force: The force exerted perpendicular to the surfaces can enhance friction; an increase in normal force usually results in a proportional increase in the frictional force.

- Material Properties: Different materials possess unique intrinsic properties that affect how they interact and resist motion.

- Environmental Conditions: Factors such as lubrication, moisture, and temperature can substantially alter frictional characteristics, either increasing or decreasing resistance.

The Role of Friction in Everyday Life

The omnipresence of friction fundamentally shapes our environment. From the simple act of walking to the intricate mechanics of automobiles, friction plays a pivotal role in maintaining safety and functionality. For instance, the ability to walk relies on static friction between shoes and the ground; without it, slipping would be inevitable. Similarly, vehicles depend on friction not only for mobility but also for braking systems, where kinetic friction decelerates the vehicle efficiently.

Applications in Engineering and Design

In engineering and design, an astute appreciation of friction allows for the optimization of various mechanisms. Engineers frequently design systems with appropriate materials and surface treatments to ensure optimal frictional characteristics. Examples include:

- Braking Systems: Effective braking relies on the precise manipulation of static and kinetic friction to halt motion without compromising safety.

- Bearings: The design of bearings often incorporates lubrication to minimize friction while balancing load-bearing capabilities, crucial for mechanical advantage.

- Assembly of Components: Friction is leveraged in fastening technologies, such as screws and bolts, where clamping forces ensure stability and reliability.

Frictional Forces in Nature

Friction is not confined to synthetic technologies; it can also be observed in natural ecosystems. The interaction between soil particles, for instance, influences erosion and sediment transport, playing a vital role in shaping landscapes. The unique frictional characteristics of biological materials, such as tree bark, assist in adherence factors crucial for plant life.

Conclusion

In conclusion, understanding the force of friction and its counteraction to motion whenever two surfaces come into contact is paramount across various fields. Frictional interactions significantly influence not only mechanical systems but also our daily experiences. By studying and harnessing the principles of friction, we can innovate and improve technologies while appreciating the complexities that govern both engineered and natural environments. The ongoing exploration of friction holds promises for future advancements in science, technology, and sustainability.