Anaerobic digesters are often likened to nature’s own recycling facilities—a transformative enigma that harnesses waste materials and metamorphoses them into renewable energy sources. At the heart of this captivating process lies biogas production, an intricate interplay of microbial action and organic degradation, creating a sustainable solution to energy generation. This article delves into the conditions resulting from employing anaerobic digesters, elucidating the biogas production process while revealing its multifaceted benefits and unique appeal.

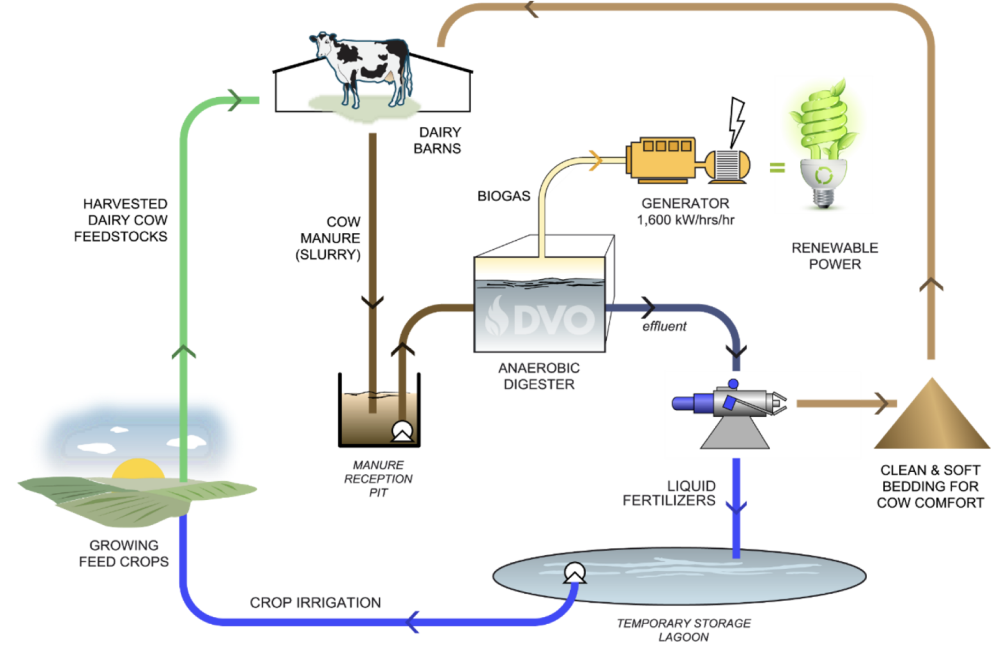

To grasp the essence of biogas production, one must first understand the structure and operational principles of anaerobic digesters. These are sealed, oxygen-free environments that accommodate anaerobic microorganisms—those that thrive in the absence of oxygen. The conditions within the digester are meticulously controlled to facilitate the optimal performance of these microorganisms. An array of organic materials, including agricultural waste, food scraps, and manure, are introduced into the digester, where they are subjected to microbial digestion through a series of biochemical reactions.

The initial phase of anaerobic digestion is hydrolysis, where complex organic matter is broken down into simpler compounds by enzymes secreted by microorganisms. This step is akin to the unearthing of buried treasure; the valuable elements locked within the organic waste become accessible, setting the stage for subsequent transformations. Following hydrolysis, the process continues with acidogenesis, wherein fermentative bacteria further decompose these simple compounds into volatile fatty acids, hydrogen, and carbon dioxide. This transitional stage is vital, as it not only maintains the digestion process but also generates substrates for methanogenesis, the final and most critical phase.

In the methanogenesis stage, a different assemblage of microorganisms, known as methanogens, converts the volatile fatty acids and other intermediate products into biogas. The biogas is rich in methane—one of the primary components—and can also contain carbon dioxide and trace gases. Herein lies the compelling allure of anaerobic digesters; they can produce biogas that serves as a potent renewable energy source, illuminating homes or fueling vehicles, while simultaneously curtailing greenhouse gas emissions. The analogy of ‘turning waste into watts’ aptly describes this transformative capability, reflecting both the ingenuity of the anaerobic digestion process and its environmental significance.

The conditions conducive to the efficient operation of anaerobic digesters hinge largely on pH, temperature, and retention time. The pH level within the digester should ideally hover around neutral (pH 6.5-8.5) to favor microbial activity. Deviations from this optimal range may inhibit biogas production or lead to process failure, much like a symphony that falters when one instrument is out of tune. Temperature also wields considerable influence—anaerobic digestion can be conducted in either psychrophilic (cold), mesophilic (moderate), or thermophilic (high) conditions, each presenting unique advantages and challenges. For instance, mesophilic digestion (approximately 30-40°C) is commonly employed due to its effective methane yield and lower energy demand for heating.

Retention time, the duration for which materials remain in the digester, is another pivotal factor influencing biogas output. A longer retention time allows for greater microbial activity and digestion of complex organic matter; however, efficiency needs to be balanced with operational costs. The art of anaerobic digestion lies in fine-tuning these parameters to achieve a symbiotic balance that maximizes biogas production while ensuring the stability of the microbial ecosystem.

Beyond the technical considerations, the socio-economic ramifications of deploying anaerobic digesters are profound. They reimagine the landscape of waste management, offering a dual perspective: waste disposal and energy creation. For farmers, anaerobic digesters present an opportunity to convert manure into a valuable resource, reducing reliance on fossil fuels and diminishing costs associated with waste disposal. The fertility of the digestate, a byproduct of the digestion process, enriches soil health, epitomizing the circular economy concept that seeks to minimize waste while utilizing resources efficiently.

Moreover, the environmental implications are paramount. Biogas produced through anaerobic digestion mitigates the release of methane, a potent greenhouse gas, from decaying organic matter in landfills. Instead of contributing to climate change, the process catalyzes the generation of renewable energy, thereby fostering a sustainable relationship between society and nature. The metaphorical ‘breath of fresh air’ offered by anaerobic digesters serves as a beacon of hope, signaling a paradigm shift towards greener practices that nurture our planet’s resources.

In conclusion, the conditions that arise from the operation of anaerobic digesters encapsulate a rich tapestry of scientific ingenuity and environmental stewardship. Biogas production is not merely a technical process; it embodies a visionary approach to energy generation and waste management, illustrating how the intersection of biology and technology can yield remarkable outcomes. As society continues to grapple with the challenges of energy conservation and waste disposal, anaerobic digesters stand poised to play a transformative role in shaping a sustainable future, proving that from waste, we can cultivate not just energy, but hope.